Posted: July 09, 2020

Contributed by: Sinjin Dixon-Warren, PhD

Electric vehicles (EV) are potentially a disruptive technology in the automotive market. They offer the promise of increased energy efficiency and the potential for reduced emissions, depending on the primary energy source used to generate the electricity. Furthermore, since electricity generally is much cheaper than gasoline, partly due to differences in taxation, EV’s promise lower operating costs. However, one downside of lithium ion batteries is that their energy density is 100 times less than gasoline (see). Even accounting for the higher efficiency of electric vehicles we would need to increase the energy density of batteries by a factor of ~5 to achieve the same weight efficiency as a gasoline powered car.

TechInsights recently completed some analysis of parts of the Chevrolet Bolt EV. According to Consumer Reports, the 2020 Chevrolet “Bolt is the first relatively affordable EV to have a robust driving range. This small hatchback is built around a large 66-kilowatt-hour battery pack that sits under the car's floor and contributes to the car's planted feel despite its tall stance. With 200 electrified horses on tap, the Bolt accelerates with gusto. A full charge takes 10 hours on a 240-volt connector, but with a rated 417 km range, owners should rarely have to fully charge the Bolt.” Our analysis has focused on the powertrain, including the inverter and the lithium ion battery pack. In this short article, we will review some of this analysis.

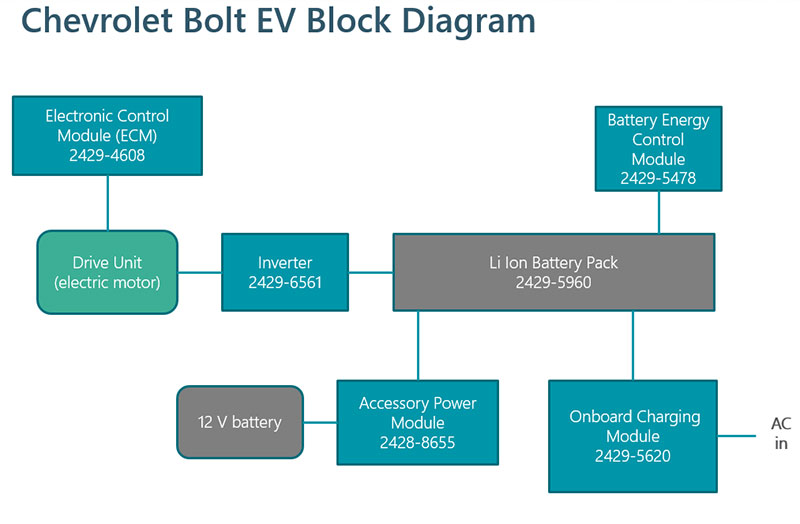

Figure 1 shows a schematic block diagram for the Chevy Bolt powertrain. The Li ion battery pack, inverter and the drive unit form the heart of the powertrain. The onboard charging module is used to convert the main AC power to the required DC power for charging the batteries. The battery control module balances the charging and discharging of the cells in the battery pack. The inverter converts the DC current from the battery to the three-phase AC required for the drive unit (electric motor). Accessory power module provides 12 V DC to run the various electrical component of the car, such as the heating fans and power windows. The ECM controls the drive unit.

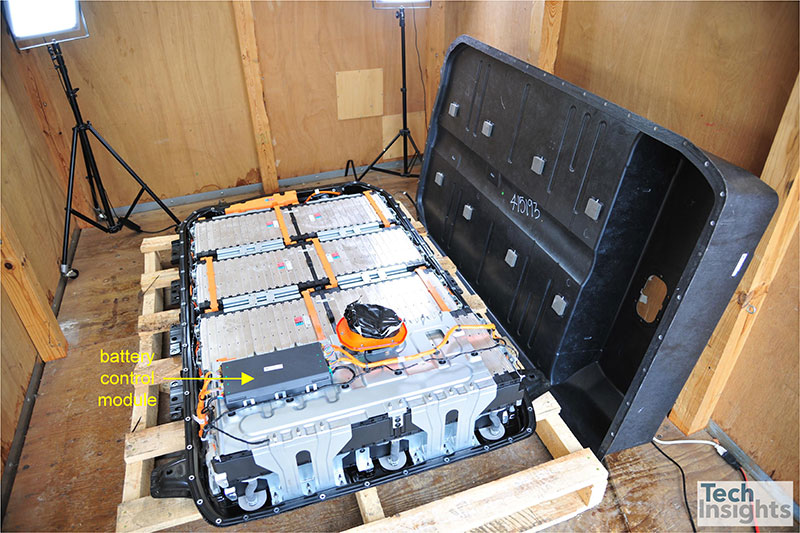

The battery pack on the Chevy Bolt is made by LG Electronics and occupies a large portion of the car’s undercarriage. Lithium ion batteries are somewhat hazardous to work with; due to the very high electrical energy density and the presence of flammable organic electrolyte materials, TechInsights performed the basic teardown work in a storage container in the parking lot of our office, as shown in Figure 2.

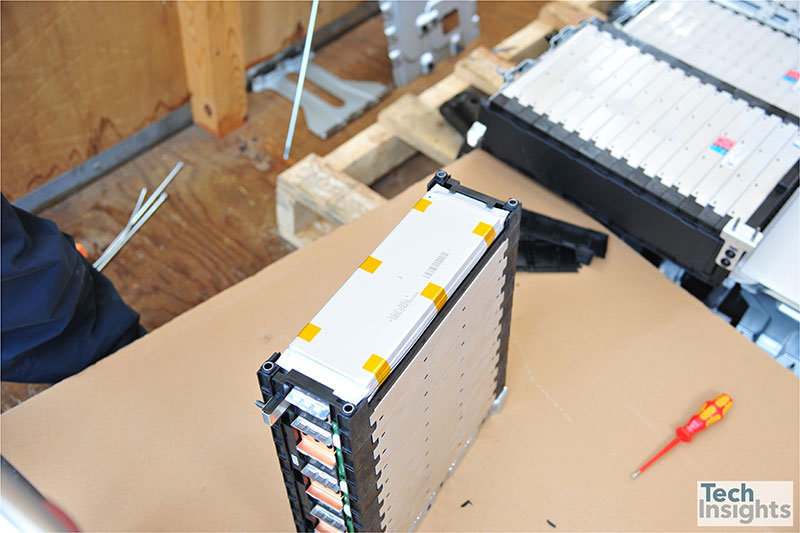

Figure 3 shows a photograph of the LG Electronics VISTA 2.0 battery pack with the cover removed. The pack is comprised of banks of cells wired in series and in parallel to generate the desired high voltage and high current. A battery control module is seen over the lower left corner of the battery. This module serves to manage the electrical and thermal load of the battery. It is very important that the battery cells charge and discharge at the same rate, to ensure thermal stability and a long life for the battery pack. A single cell module was removed from the battery pack and then disassembled to release a single SB035Z6 battery cell for further analysis, as shown in Figure 4 and Figure 5. The SB035Z6 battery cell was then carefully discharged prior to performing an analysis of the internal structure of the battery cell.

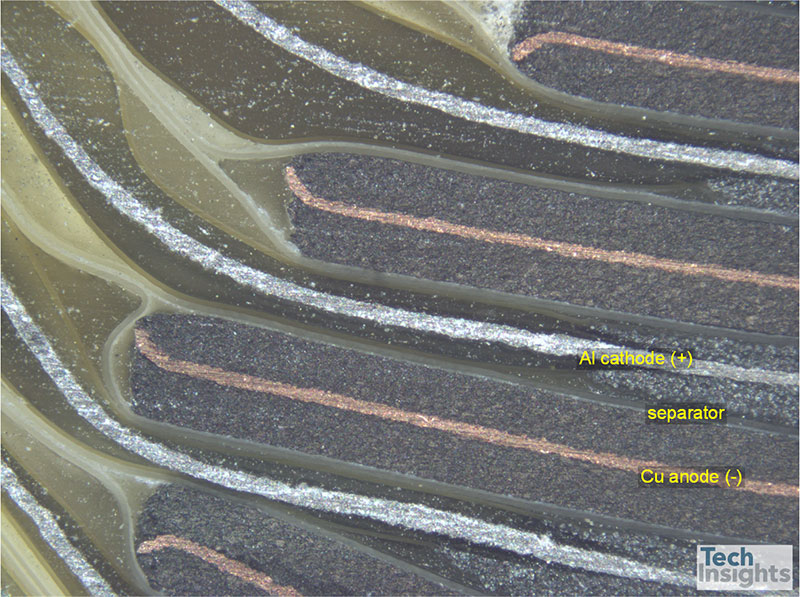

An optical cross-sectional image of the internal structure of the SB035Z6 battery cell is shown in Figure 6. Further discussion of lithium ion battery technology can be found in our recent article published by EEPower.com. The cell is formed likely using LG’s stack and fold structure, with layers of anode (-) and cathode (+) materials separated by an organic separator material. The area shown in Figure 6 is near the edge of the battery cell. The separator and Al cathode electrode extend further than the Cu anode electrode, and the separators ensure complete electrical separation of the anode and cathode active materials.

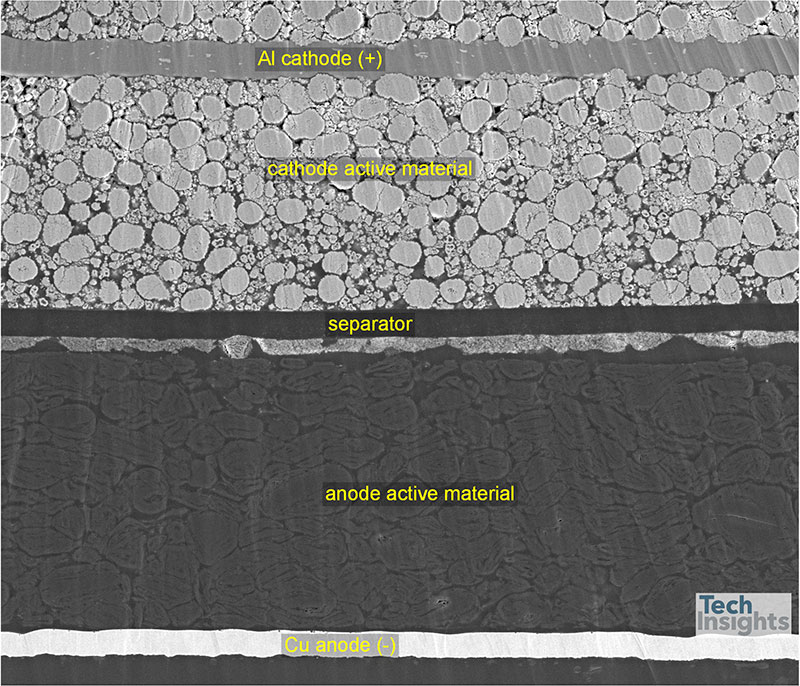

A more detailed SEM cross-sectional view of the cell structures is presented in Figure 7. Our analysis found the cathode active material to be formed with LiNiMnCoO2 particles, while the anode active layer is formed using graphite. The separator comprises an organic film coated on one side with a metal oxide. The details of the structure and materials of the LG Electronics SB035Z6 cell differ from that found in TechInsights’ recent analysis of the Samsung SDI EB-BG977ABU Lithium-Ion Battery [1]. This battery was extracted from the Samsung Galaxy S10 5G SM-G977U smartphone and featured a LiCo2 cathode Substituting Ni and Mn for Co has two advantages. First, it results in a lower cost, since cobalt is expensive and second, substituting Ni gives a higher operating voltage, which leads to higher efficiency.

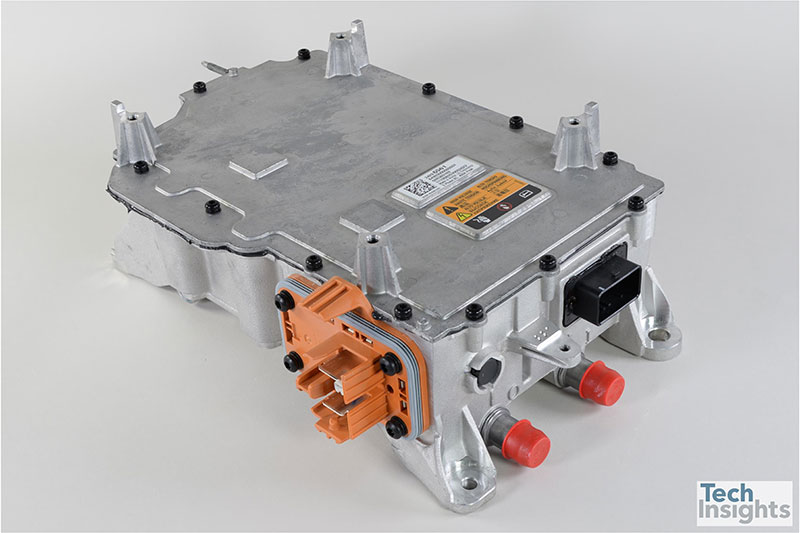

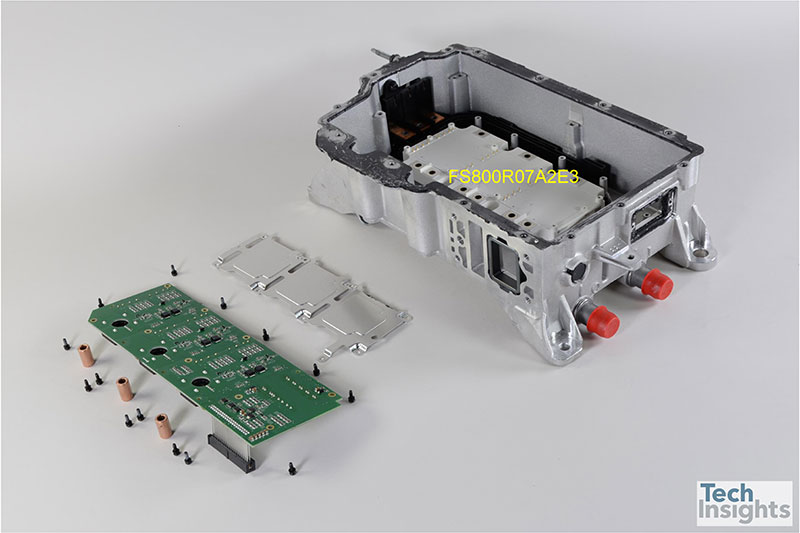

The LG Electronics VISTA 2.0 battery pack directly feeds power to the LG Electronics 2429-6561 single power inverter module, shown in Figure 8. The lid was removed from the inverter module and two printed circuit boards (PCBs) were removed, revealing a large Infineon FS800R07A2E3 IGBT3 (650 V 800 A) power module mounted in the bottom of the die cast aluminum case, as shown in Figure 9. This power module provides the 3-phase AC power required to drive the electric motor of the drive unit.

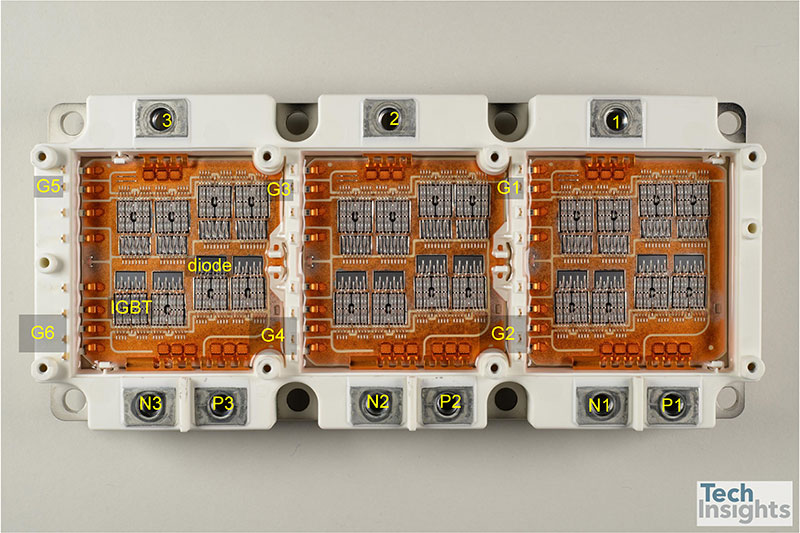

Figure 10 shows the Infineon FS800R07A2E3 IGBT3 with the ceramic lid removed. The device is formed as three independent half-bridge IGBT power stages, each comprising of four pairs of IGBT dies and four diode dies. The FS800R07A2E3 is an IGBT3 hybridpackTM2 power module that features trench gates and field stop implants.

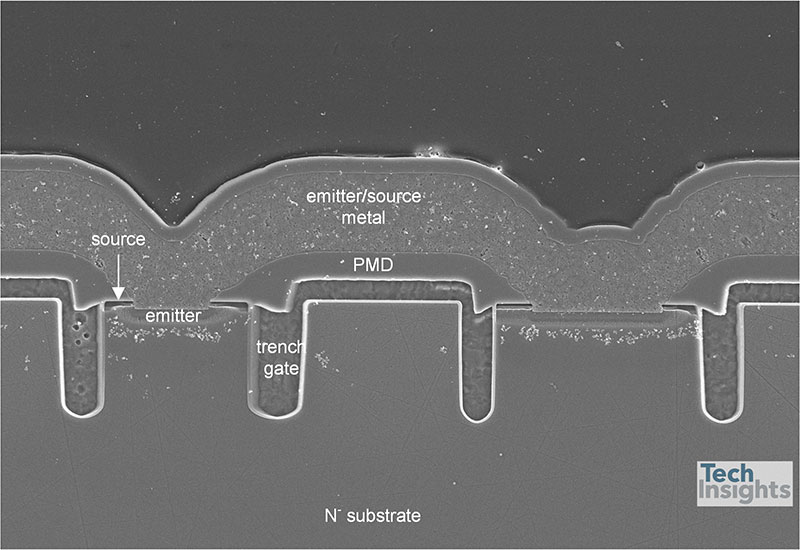

A delineated SEM cross-section of one of the IGBT dies found in the FS800R07A2E3 is shown in Figure 11. The vertical device has a top-side emitter/source metallization with trench gates. TechInsights has analyzed several IGBT trench gate IGBT technologies, including most recently the more advanced IGBT7 technology found in the InfineonFP10R12W1T7B11BOMA1 [2].

Hybrid and EV automotive technologies depend on a wide range of power electronics and Li ion battery technologies. The comparison with the author’s first car, a 1983 Toyota Corolla, is extraordinary. The 1983 Corolla features a mechanical distributor, that controlled the spark plug firing, and likely the most sophisticated piece of electronics was the AM/FM radio, which featured mechanical push button tuning. By contrast, modern hybrid and EV vehicles, and even conventional gas-powered cars, are awash with sophisticated electronics.

TechInsights provides reverse engineering and analysis services that address products in the power electronics market. Our Power Semiconductor subscription provide insights into emerging power semiconductor products as they enter mass production in high-volume applications. For more information please contact us at info@techinsights.com.

1 Samsung SDI EB-BG977ABU Lithium-Ion Battery Exploratory Analysis, TechInsights, EXR-1909-801.

2 Infineon FP10R12W1T7B11BOMA1 TRENCHSTOP IGBT7 Power Essentials Summary, TechInsights, PEF-1912-801.