Oppo Find X5 Pro improves Anti-Shake Technology with 5 axis image stabilization

John Scott-Thomas

The Oppo Find X5 Pro was released in March, 2022 and introduce 5 axis optical image stabilization. This allows a putative x3 improvement in anti-shake performance.

TechInsights recently performed an analysis in the CIS Package channel, to look at the stabilization mechanism and the overall camera design. The camera has become brighter (f/1.7 compared to f/1.8 previously). The lens stack uses seven lenses with the top lens being glass (with sodium, aluminum and potassium additives); this results in a claimed 77% reduction in chromatic aberration. The lower six lenses are more conventional plastic with silicon oxide and titanium oxide coating used to reduce flaring. A Sony IMX766 sensor feature quad Bayer color arrays (that is, 2×2 pixel groups have the same color of filter) and each 2×2 pixel group shares one On Chip Lens. Omni-direction PDAF on each pixel allows accurate focussing in the horizontal and vertical directions across the field of vision. The image processing and camera control is performed using an in-house designed image signal processor, called the MariSilicon X NPU. Swedish company Hasselblad collaborates with Oppo, with the Hasselblad name brand featured on the back of the camera. Oppo claims to be using Hasselblad color routines and the 13 channel spectral sensor on the back of the phone likely provides color balancing information to the processor.

Now, back to the marquis feature of this camera; the 5 axis image stabilization mechanism. This is done by combining a sensor shift actuator with a lens barrel actuator. The sensor shift has three axes of freedom; two translations and one rotation about the axis perpendicular to the sensor plane. The remaining two degrees of freedom are performed using the lens barrel to rotate about two axes.

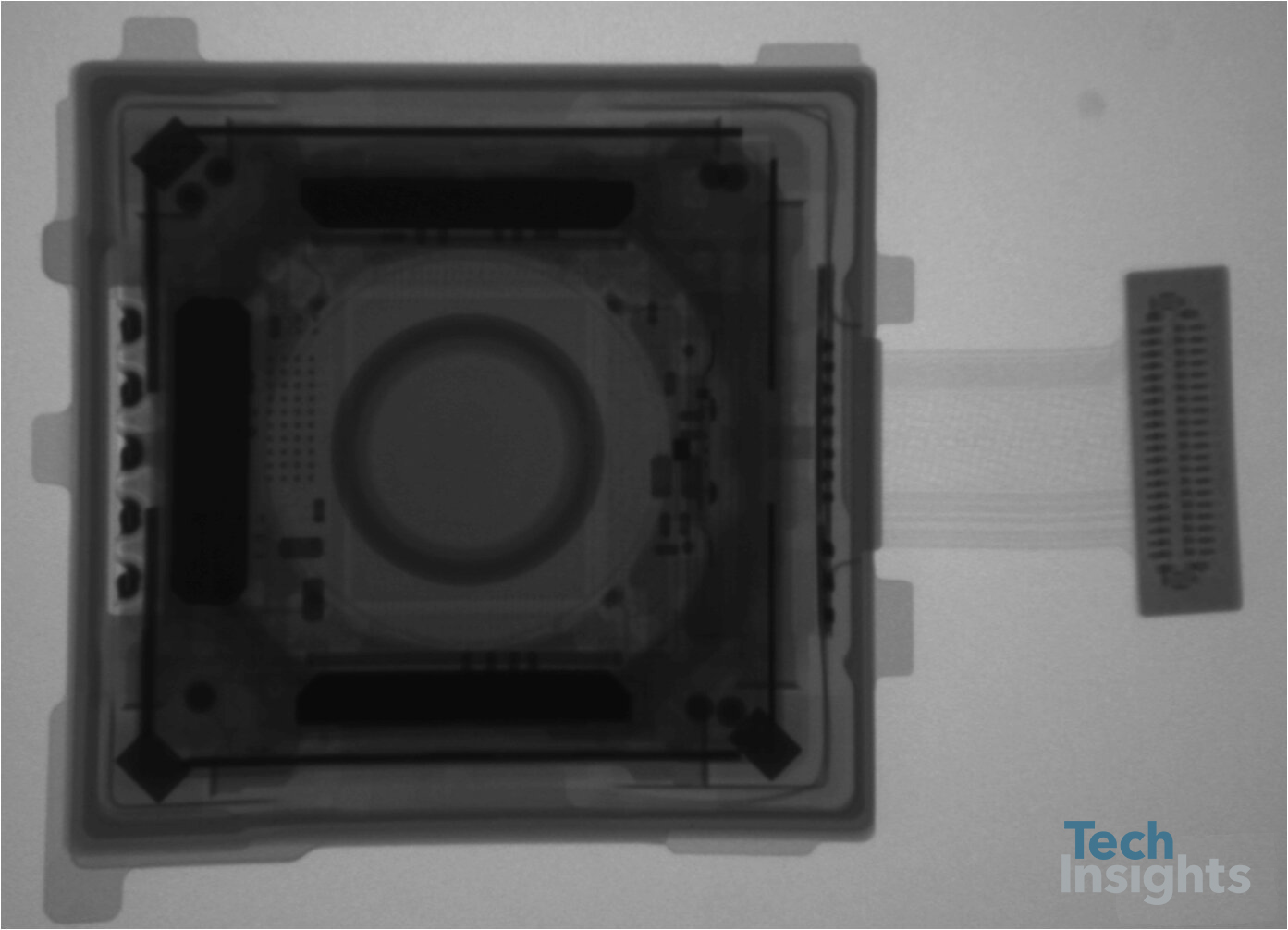

Consulting Figure 1, an X-ray image of the intact camera shows the annular bezel that is placed between lenses 5 and 6 of the lens stack. To the left of the bezel are the ball bonds that connect the Sensor driver IC to the Image sensor PWB (Printed Wiring Board). Magnets are used to move the lens barrel; the top and bottom magnets are symmetrical about the principle optical axis, while the left and right magnets are asymmetric. The cross-section of the camera that is provided in the report (Package report PKG-2204-804) shows a sophisticated package housing the lens barrel. The main lens barrel magnets are proximate to a PWB that is placed on the roof of the module. The small magnet is side mounted and proximate to a side mounted OIS chip. Yet another PWB is placed on the side of the module.

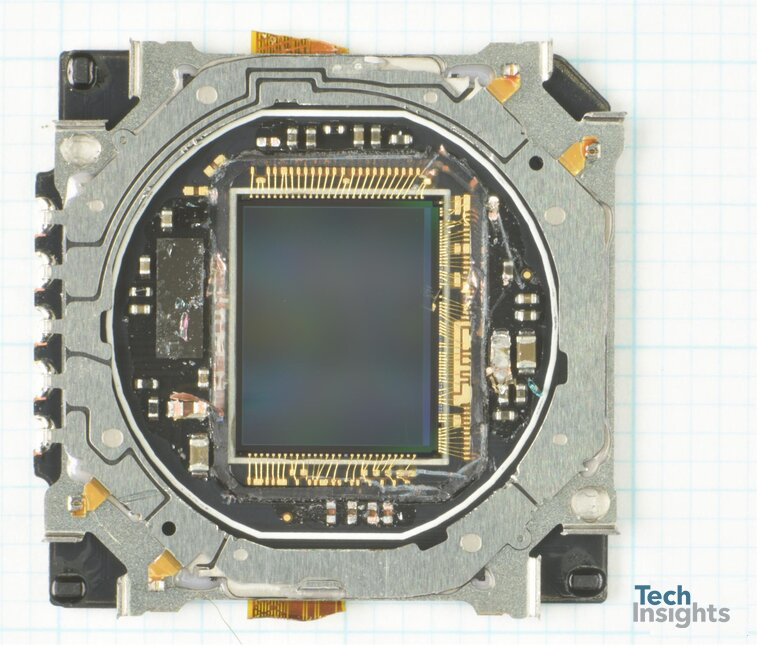

The sensor shift mechanics are a different matter, as shown in Figure 2. Here, the lens barrel has been removed exposing the Sony IMX766 sensor; a 50 MP back-side illuminated sensor with quad Bayer color filter array and a 2×2 on-chip lens.. A protective cover over the wire bonds has been removed, revealing 133 bond pads and 118 wire bonds. Around the circular opening of the sensor is a set of shape memory alloy plates that control the shifting and rotation of the sensor substrate. At various points, up to three concentric plates control the motion providing the required three degrees of freedom. A Cu-Ni-Al alloy frame houses the imager, lens barrels and actuator.

It takes a lot of ingenious technology to achieve five degrees of motion in a camera module; there are plenty more details in TechInsights’ recent package report “5-Axis Stabilized 50MP Wide-Angle Camera Module from Oppo Find X5 Pro Package Analysis Report”, PKG-2204-804.